SRF-254-1600C Planer planer – surface planer. Passport, diagrams, description, characteristics

SRF-254-1600C Portable woodworking planer thicknesser

Schemes, description, characteristics

Information about the manufacturer of the thicknessing machine SRF-254-1600S

Thickness woodworking machine manufacturer SRF-254-1600S is a company Zubr UWC, COMPANY. The company was founded in 2005 and is located in the city of Mytishchi. Website address: http://www.zubr.ru

Machine tools manufactured by Zubr OVK

Zubr SRF-254-1600S Planer planer. Purpose, scope

Planer planer SRF-254-1600S, having the functions of planer and jointer, allows you to plan workpieces from wood up to 120 mm thick and 254 mm wide, the planer shaft has 2 knives and a rotation speed of 9000 rpm, electric motor power 1.6 kW, feed speed 6 m/min.

The planing thicknesser of the desktop combined machine Zubr SRF-254-1600S is used for planing and carpentry processing of wood blanks to predetermined height dimensions using two rotating knives.

The system of adjustments and additional devices provide high accuracy of operations and ensure safe operation.

A vacuum cleaner can be connected to remove sawdust.

The SRF-254-1600C machine is designed for work under medium-intensity loads in areas with a temperate climate with a characteristic temperature of +5 to +35°C, relative humidity of no more than 80% and no direct impact of precipitation and excessive dust content in the air.

Easy transition from one operation to another. Polished work tables make it easier to feed the workpiece into the cutting area. Depending on the operation being performed, the dust collector nozzle can be easily adjusted to the desired position, ensuring a clean workplace.

Distinctive features of the thicknessing machine SRF-254-1600C:

The compact portable planer planer Zubr SRF-254-1600C is designed for planing wooden blanks in a carpentry workshop or at a construction site.

- Economic motor with overload protection

- Belt drive protects the motor from overload and reduces noise during operation

- Magnetic starter eliminates spontaneous start-up of the machine after a temporary power outage

- Automatic workpiece feed (thickness gauge)

- Cast work table with polished surface for excellent glide

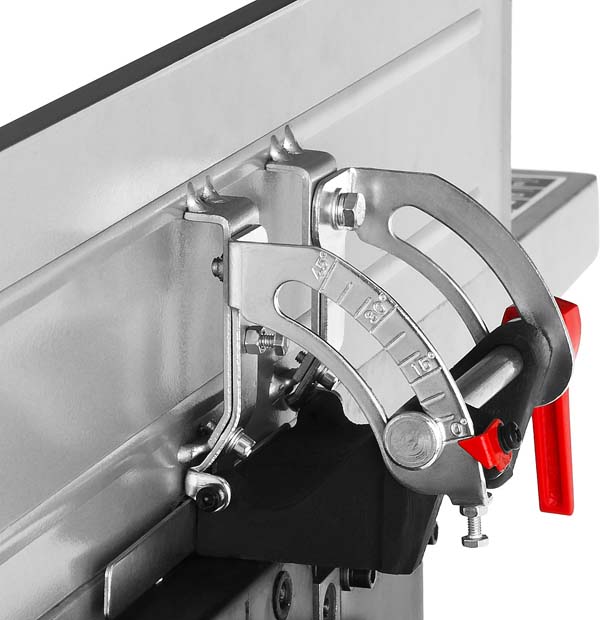

- Guide stop tilt adjustment from 0 to 45°

- The high speed of rotation of the knife shaft ensures a clean surface

- Two high speed steel blades suitable for cutting both soft and hard woods

- Polished work tables make it easier to feed the workpiece into the cutting area

- The dust collector nozzle is easily installed in the desired position, ensuring a clean workplace

- Stand for easy installation of the machine

Delivery set of the SRF-254-1600C machine

- Machine – 1 pc.

- Parallel emphasis with fastening – 1 piece.

- Protective bar with bracket – 1 pc.

- A set of keys – 1 set.

- Template for installing knives – 1 pc.

- Clamp – 2 pcs.

- Dust collector – 1 pc.

- Rubber support – 4 pcs.

- Fasteners – 1 set.

- Operation manual – 1 copy.

- Stand – 1 pc.

SRF-254-1600S General view of the thicknessing machine

Photo of planer planer SRF-254-1600C

SRF-254-1600S machine in jointer mode. Front view

SRF-254-1600S machine in jointer mode. Back view

Thrust bar tilt unit on the SRF-254-1600C machine

SRF-254-1600S machine in jointer mode. Back view

Srogalny shaft and a protective level of the SRF-254-1600C machine

SRF-254-1600S machine in thickness gauge mode. Front view

Machine SRF-254-1600S in thickness gauge mode

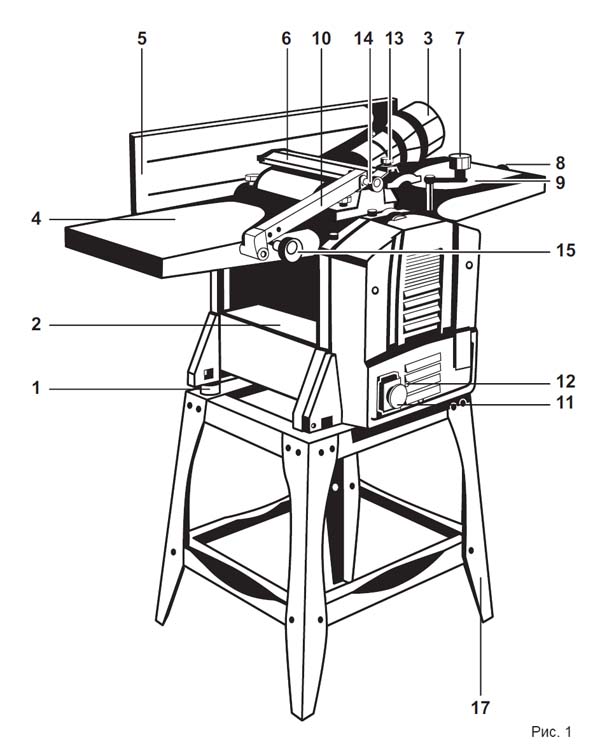

The location of the components and controls of the thicknessing machine SRF-254-1600C

Location of the components of the thickness gauge SRF-254-1600C

- Rubber feet

- Surface thickness desktop

- Dust extraction

- reception table

- Parallel stop

- Protective bar

- Thicknessing table height adjustment handle

- Depth adjustment knob

- Serving table

- Protective bar bracket

- magnetic switch

- Thermal relay button

- Protective bar lock

- Protective bar angle lock

- Bracket position lock

- Screw

- Stand

Thickening on the machine SRF-204-1500

Planing to size in thickness (thickening) is necessary to obtain a workpiece of a given thickness and, at the same time, to create a flat surface parallel to the opposite side of the board. When working, it is necessary to take into account not only the width of the workpiece, but also the hardness of the wood, its moisture content, straightness, the direction of the layers and their structure.

The thickness of the processed workpiece is set by the distance set between the planer knives and the work table, which is adjusted by handle 7.

- Install the dust collector as shown in fig. 4, and connect it to the hood.

- Set the desired planing depth on the scale.

- Turn on the product, put the workpiece on the working table of the thicknesser, perpendicular to the cutter shaft.

- Slowly feed the workpiece forward until it contacts the feed roller. If the thickness of the workpiece is variable, then feed the workpiece with the thicker side.

After picking up the workpiece by the feed roller, go to the back of the machine and take the workpiece.

Do not apply excessive force when feeding the workpiece. The feed is carried out automatically, at the speed for which the machine is designed. If the planing drum is jammed, the machine must be switched off immediately with the switch and the drum freed. Inspect it for damage or deformation. Then briefly (for 3-5 seconds) turn on the machine at idle and check the sparking of the brushes on the collector. The presence of increased sparking or circular fire indicates a burnout of the motor windings.Further operation of such a machine is prohibited. In the absence of increased sparking, it is necessary to turn on the machine without load for 15-30 seconds to accelerate the cooling of the electric motor. After that, you can continue to work.

During operation, do not allow foreign objects (coarse-grained dust and chips) to enter the cooling air intake area of the electric motor. This may damage the motor.